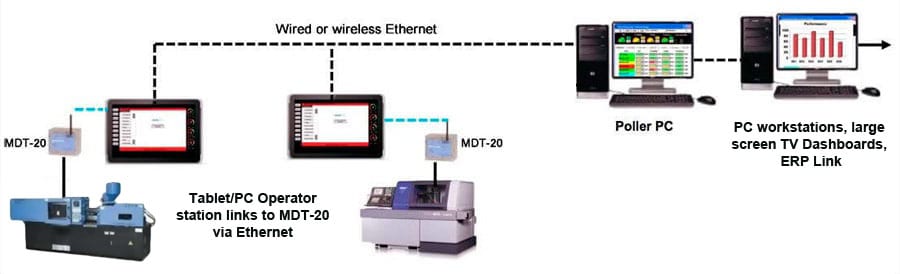

One central, usually cloud-based system, streamlines processes and data flow along the production line and between departments.

Digital production and compliance checks replace pen and paper processes, creating full and real-time visibility. An MES saves a manufacturing business time as operations can run smoother and more effectively due to the digitalization of the production floor. Manufacturing execution systems (MES), or manufacturing software, make production and compliance processes more efficient and reduce costs. What is a manufacturing execution system? Let’s start with some basic definitions before we have a closer look at how to develop a business case and calculate the ROI for a manufacturing execution system. So, how do you determine the ROI for a smart manufacturing software solution and how can you use this method to add real value to your manufacturing business? However, manufacturers want to know beforehand what costs are involved, how disruptive the implementation of a digital manufacturing execution system might become and particularly, what return on investment they can expect from digitizing the production floor.ĭifficulties with determining the exact return on investment (ROI) of implementing a manufacturing execution system might lead to the assumption that business risks outweigh the potential value, resulting in delays or even refusal of implementing such a system. Digitizing the production floor is a major investment in the efficiency and success of a manufacturing business.

0 kommentar(er)

0 kommentar(er)